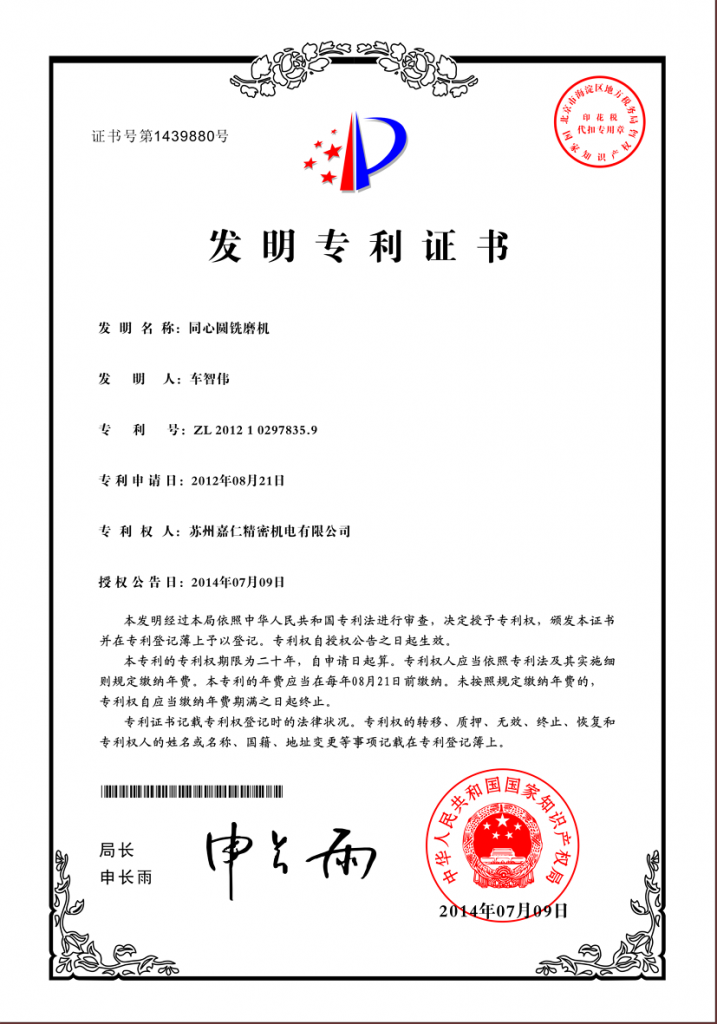

热烈祝贺我公司获得一项国家发明专利

专业光学设备生产商

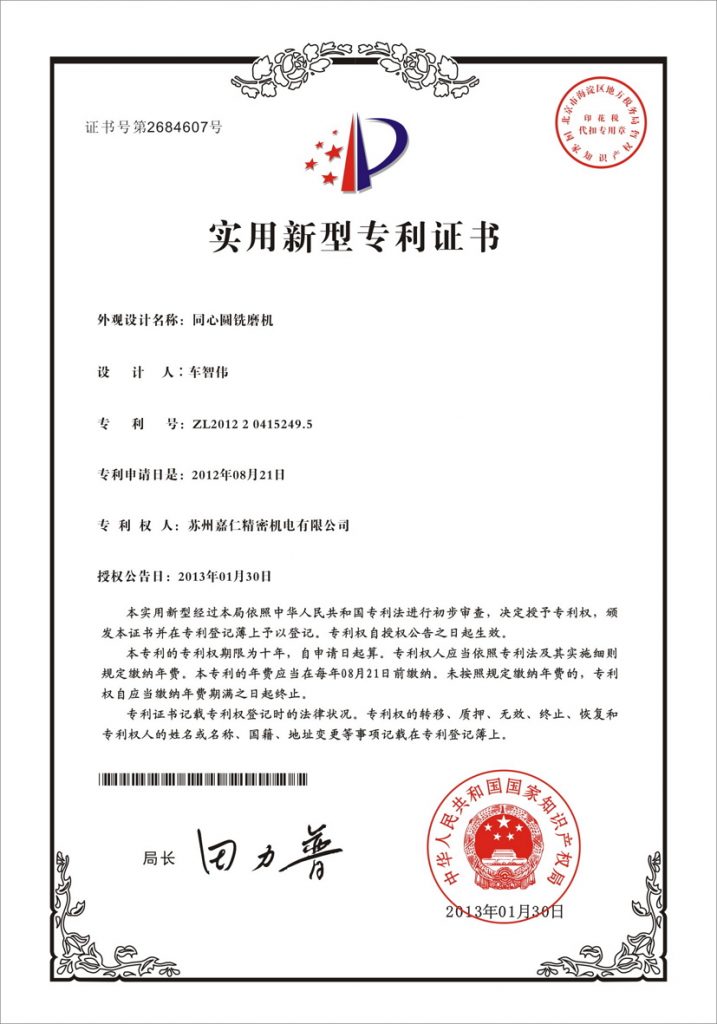

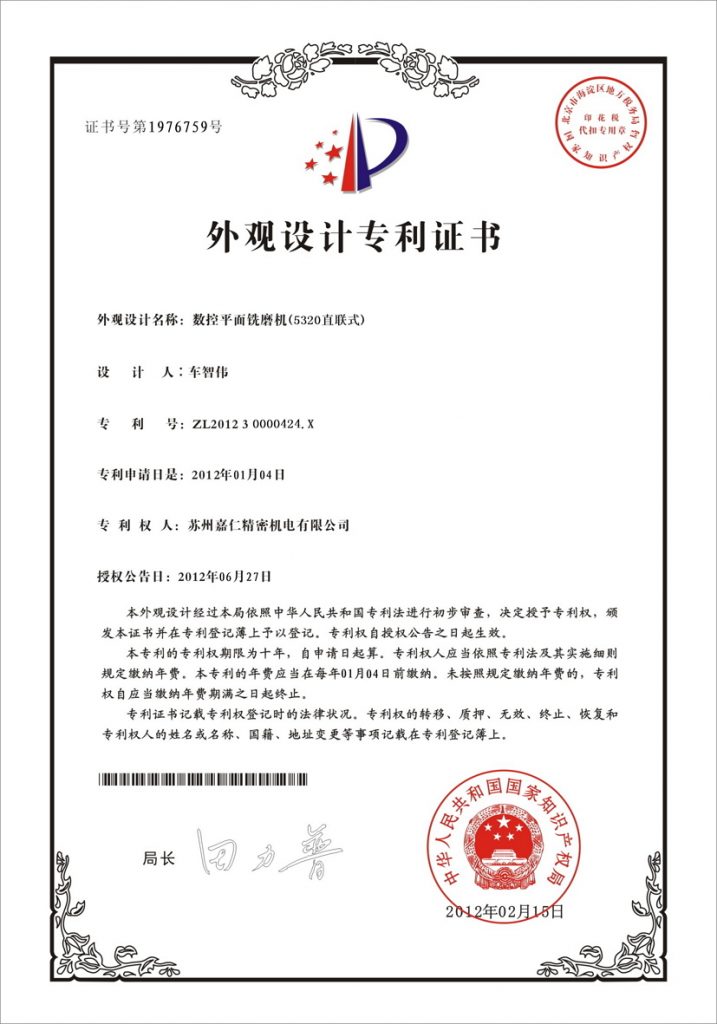

苏州嘉仁精密机电有限公司是一家设计、研发、生产、服务、销售为一体的自动化数控机床制造商。公司从事自动化行业数十年,生产技术力量强大,设计团队经验丰富,拥有多项发明专利。已开发出数十种不同系列的机床,广受客户好评。

技术团队文化高,骨干多。拥有研究生以上学历职工占总员工5%,拥有大专以上职工占总员比例工超过50%。公司重视技术研发,重视核心技术的投入,每种产品都拥有多项发明专利。在产品质量上严格把关,技术上不断研发创新,售后服务上由总经理亲自带队,为客户提供全方位的服务。

最早在上世纪90年代,我们国家开始引进数控铣磨机来替代老式机床,提高生产效率。我们公司也早在00年开始研制数控铣磨机机,当时起步早连显示屏幕都只有黑白的。如今数控铣磨机已经涉及行业多,适用于各种材料的加工。比如光学玻璃:冕牌玻璃,火石玻璃等各种无色光学玻璃;红外材料:红外熔石英,宝石,硒化锌;晶体材料:三硼酸锂,LBO,相偏硼酸钡,BBO,掺钕钇铝石榴石,Nd:YAG,人造蓝宝石,AL203等。到如今我们公司有一套非常成熟的经验,对于各种产品加工更加专业化,后续工艺更加科学化,使得机床的各种参数、配置更加个性化,配套设施更加人性化。能为客户解决各种加工难题。

现在我们已经累计了众多的客户,遍布全国,涉及海外。作为一家专业从事光学冷加工设备生产和研发的本土企业,我们围绕光电产业研发出数十种产品,设备精度已达到甚至超过国际现有水平。

当下面对国内光电行业迅猛发展,为适应未来新兴技术发展要求,苏州嘉仁精密不断提高自身研发水平,完善产品性能,扩大生产规模,丰富产品种类,增加售后服人员,为帮助越来越多的客户减少对昂贵进口设备的依赖而不断努力。

Suzhou Jiaren Precision Machinery and Electricity Co., Ltd. is a manufacturer of automatic CNC machine tools integrating design, research, development, production, service and sales. The company has been engaged in automation industry for decades, with strong production technology, rich experience in design team, and many invention patents. Several dozens of different series of machine tools have been developed, which are well received by customers.

–

Technical team has a high culture and many backbones. Employees with postgraduate or higher education accounted for 5% of the total staff, and those with college or higher accounted for more than 50% of the total staff. The company attaches great importance to technological research and development, and to the investment of core technologies. Each product has a number of invention patents. Strict quality control, technological innovation and continuous research and development, after-sales service led by the General Manager personally, to provide customers with a full range of services.

–

As early as in the 1990s, our country began to introduce CNC milling mill to replace the old machine tools and improve production efficiency. Our company also began to develop CNC milling mill as early as 2000. At that time, even the display screen was black and white. Nowadays, CNC milling mill has involved many industries and is suitable for processing various materials. For example, optical glass: crown glass, flint glass and other colorless optical glass; infrared materials: infrared fused quartz, gemstone, zinc selenide; crystal materials: lithium borate, LBO, barium metaborate, BBO, Nd: YAG, artificial sapphire, AL203 and so on. Now our company has a very mature set of experience, for a variety of products processing more specialized, follow-up process more scientific, making machine tool parameters, configuration more personalized, supporting facilities more humane. All kinds of processing problems for customers can be solved.

Now we have accumulated a large number of customers, all over the country, involving overseas. As a local enterprise specializing in the production and research of optical cold processing equipment, we have developed dozens of products around the optoelectronic industry, and the accuracy of the equipment has reached or even exceeded the existing international level.

–

With the rapid development of domestic optoelectronic industry, in order to meet the requirements of new technology development in the future, Suzhou Jiaren Precision has continuously improved its R&D level, improved product performance, expanded production scale, enriched product categories, increased after-sales service personnel, and made continuous efforts to help more and more customers reduce their dependence on expensive imported equipment.

我们公司是一家设计、研发、生产、服务、销售为一体的自动化数控机床制造商。公司从事自动化行业数十年,生产技术力量强大,设计团队经验丰富,拥有多项发明专利。已开发出数十种不同系列的机床,广受客户好评。

技术团队文化高,骨干多。拥有研究生以上学历职工占总员工5%,拥有大专以上职工占总员比例工超过50%。公司重视技术研发,重视核心技术的投入,每种产品都拥有多项发明专利。在产品质量上严格把关,技术上不断研发创新,售后服务上由总经理亲自带队,为客户提供全方位的服务。

最早在上世纪90年代,我们国家开始引进数控铣磨机来替代老式机床,提高生产效率。我们公司也早在00年开始研制数控铣磨机机,当时起步早连显示屏幕都只有黑白的。如今数控铣磨机已经涉及行业多,适用于各种材料的加工。比如光学玻璃:冕牌玻璃,火石玻璃等各种无色光学玻璃;红外材料:红外熔石英,宝石,硒化锌;晶体材料:三硼酸锂,LBO,相偏硼酸钡,BBO,掺钕钇铝石榴石,Nd:YAG,人造蓝宝石,AL203等。到如今我们公司有一套非常成熟的经验,对于各种产品加工更加专业化,后续工艺更加科学化,使得机床的各种参数、配置更加个性化,配套设施更加人性化。能为客户解决各种加工难题。

现在我们已经累计了众多的客户,遍布全国,涉及海外。作为一家专业从事光学冷加工设备生产和研发的本土企业,我们围绕光电产业研发出数十种产品,设备精度已达到甚至超过国际现有水平。

当下面对国内光电行业迅猛发展,为适应未来新兴技术发展要求,苏州嘉仁精密不断提高自身研发水平,完善产品性能,扩大生产规模,丰富产品种类,增加售后服人员,为帮助越来越多的客户减少对昂贵进口设备的依赖而不断努力。

Suzhou Jiaren Precision Machinery and Electricity Co., Ltd. is a manufacturer of automatic CNC machine tools integrating design, research, development, production, service and sales. The company has been engaged in automation industry for decades, with strong production technology, rich experience in design team, and many invention patents. Several dozens of different series of machine tools have been developed, which are well received by customers.

–

Technical team has a high culture and many backbones. Employees with postgraduate or higher education accounted for 5% of the total staff, and those with college or higher accounted for more than 50% of the total staff. The company attaches great importance to technological research and development, and to the investment of core technologies. Each product has a number of invention patents. Strict quality control, technological innovation and continuous research and development, after-sales service led by the General Manager personally, to provide customers with a full range of services.

–

As early as in the 1990s, our country began to introduce CNC milling mill to replace the old machine tools and improve production efficiency. Our company also began to develop CNC milling mill as early as 2000. At that time, even the display screen was black and white. Nowadays, CNC milling mill has involved many industries and is suitable for processing various materials. For example, optical glass: crown glass, flint glass and other colorless optical glass; infrared materials: infrared fused quartz, gemstone, zinc selenide; crystal materials: lithium borate, LBO, barium metaborate, BBO, Nd: YAG, artificial sapphire, AL203 and so on. Now our company has a very mature set of experience, for a variety of products processing more specialized, follow-up process more scientific, making machine tool parameters, configuration more personalized, supporting facilities more humane. All kinds of processing problems for customers can be solved.

Now we have accumulated a large number of customers, all over the country, involving overseas. As a local enterprise specializing in the production and research of optical cold processing equipment, we have developed dozens of products around the optoelectronic industry, and the accuracy of the equipment has reached or even exceeded the existing international level.

–

With the rapid development of domestic optoelectronic industry, in order to meet the requirements of new technology development in the future, Suzhou Jiaren Precision has continuously improved its R&D level, improved product performance, expanded production scale, enriched product categories, increased after-sales service personnel, and made continuous efforts to help more and more customers reduce their dependence on expensive imported equipment.

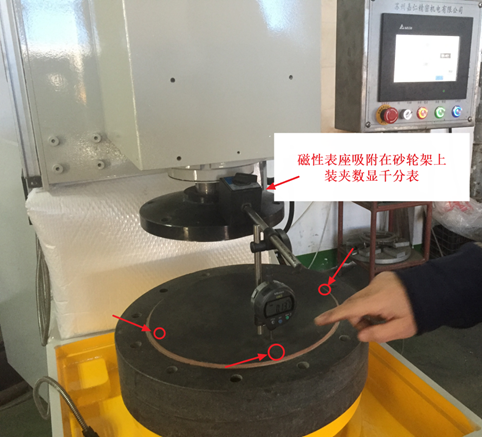

准备磁性表座和数显千分表各一个,红色圆圈的位置。按图所示装夹,使得千分表可以测量到。

先调整左右,如果前面的数字 和右边的接近,调左边;如果前面的数字 和左边的接近,调右边。

如视频上,所以后面的视频我们以右边归零为基准,开始调节右边。

视频上,当左边归零时,右边高度为0.015mm,前面高度为0.022mm。我们先调整左右,等左右调平以后,再调整前面。

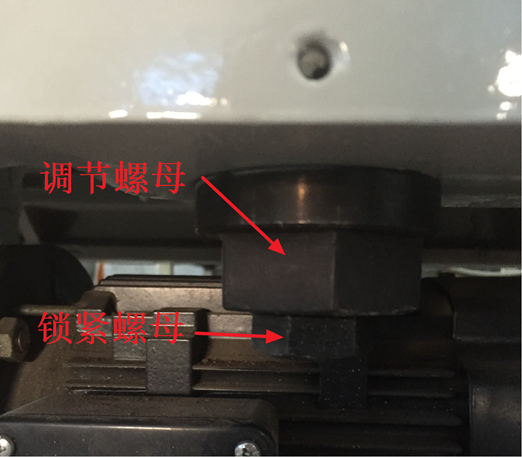

调节位置。松开锁紧螺母,调节调节螺母。

松开锁紧螺母会稍微抬高一点点,这会影响我们调整水平。

之前我们的尺寸是-0.015mm,我们要调高0.015mm,但是松开锁紧螺母后,数值变成了0.002mm,此时我们需要把继续+0.015mm,才会正确调平。

调整0.015mm,大约要调整螺母 10°左右,但一切以实际为准。

视频里,我们把左边的高度通过调节螺母调高了0.015mm,然后再把锁紧螺母调死,使得其固定住,这时候数值大约有0.005mm的变化。

视频里,我们通过两次调整使得,左右终于数值一致,0对0。一般情况下0.002mm左右都是可以接受的,但是误差越小越好。如果工作台表面不干净,凹凸不平,或者千分表测量点正好超出了台面范围,可以用一块大的平整的玻璃或是大理石板放在工作台上,越平越好。

现在我们左右调好了。然后开始调节正前方。

调好了左右以后,我们发现正前方变成了0.012mm,我们需要把它调整到0.002mm。以我们的经验的来说,如果加工玻璃等软的材料,正0.002mm左右就够了,如果加工蓝宝石,99陶瓷,需要调成正0.005mm。

我们松掉锁紧螺母以后,多了0.02mm多,变成了0.038mm,然后我们直接调整到了-0.014mm。这里不是调多了,是因为前面抬高了以后,左右两边后面的点也会调高。这时候-0.014mm不是真实数值,需要把千分表量到后面左右两边的时候归零,以左边或右边任意一点作为基准点归零,然后再重新测量正前方。

视频中,我们归零后,正前方重新测量下来是0.009mm,我们需要继续调整。

正前方一般一次调不好,需要多调整两下。我们刚刚用调整螺母调整了0.02mm左右,然后锁紧了螺母,最后测量了发现只变化了-0.003mm。这和我们需要的-0.01mm的量差了很多。需要我们多调整一点。

然后我们多调整了几下,然后以左边为基准归零,正前方的数值变成了0.004mm,但是右边变成了-0.004mm。这是正常现象,左右会有稍微变化,所以我们每次调整后,必须用千分表左右前后重复测量一次。

但是误差距离我们期望值只有0.005mm以内,所以这次调整我们没有松开锁紧螺母去调整那个调整螺母,而是只调整锁紧螺母。把锁紧螺母调的更紧一点得到+0.002mm,或者松一点得到-0.002mm。

最后我们通过反复的调整,使得左边为0.000mm,

正前方为0.002mm,右边为0.000mm。

调整完毕后,如果台面面型在0.002mm左右,面型误差不大的时候,不需要自磨台面。但是如果机床使用时间长了,工作台磨损了,面型误差很大的时候,调整完毕后需要把面型自磨一次。自磨后再重新测量,确保误差在0.002mm以内。

一种可以把铣磨机和公司内部质量管理软件相连的系统软件。

该软件可以根据客户要求定做功能,比如打印功能,摄像头监控机床,集成微信小程序,

视频描述。选取玻璃底板 140-D039,

需要加工的产品粘好后,在excel表格内,填入加工人员,产品编号,毛胚高度,需要加工后的高度。

把140-D039玻璃底板放到智能铣磨机上,固定好,准备加工。用扫码枪扫取玻璃底板编号。我们的软件系统,会自动把公司局域网上excel表格内,毛胚高度,加工后的产品高度输入机床内。

点击确定后,机床开始加工。

加工完成后,软件可以把加工后的参数自动保存到excel表格内指定位置。以方便质量体系的管理和下一道工艺的参数读取。